The final topic we'll cover in Spacecraft Systems is fluid systems. A fluid system is any system that uses a working fluid, liquid or gas, to do work. Gasses and liquids are both fluids, they flow when subjected to a shear stress.

Liquids are incompressible, their volume does not change under pressure. This is because liquids have constant volume. Gasses, on the other hand, are compressible. Their density and volume change with their pressure.

Because fluids can flow under stress they will naturally move from areas of high pressure to areas of low pressure. Because of this the pressure in a confined fluid is the same everywhere. Known as Pascal's Law this property means that the pressure at one wall containing a fluid is the pressure at all the walls.

Pascal's law allows fluids to transmit force. Consider the illustration below. When piston one is pressed down pistons two and three raise up.

How far pistons two and three raise up depends on how far piston one is pressed and how wide the pistons are. Remember that the volume of a liquid doesn't change under pressure. So the volume that is compressed in piston one is the volume of pistons two and three that raises up. Volume here is the cross sectional area of the piston times how far up or down it moves.

What this means is that we can construct a device that uses a fluid to take a force from one area and relay it to another. We do so by increasing the pressure at one end of the fluid. Remember that pressure is a force divided by the area. So by creating a pressure at one end we create a force at the other end that equals the pressure times the area we're working over.

It also means that the working fluid can amplify our force. If we push down on a cylinder with a small area we get a high pressure for our force. If it's attached to another cylinder with a large area that pressure produces more force than we had to put in. Similar to how a lever can amplify force by increasing the moment.

In a system that transmits force through a fluid we can use either a liquid or a gas as our working fluid. Hydraulic systems use a liquid, often water or oil, as their working fluid. Pneumatic systems use a gas, usually air or carbon-dioxide. Spacecraft often use helium as a working fluid. It is stored as a cryogenic liquid but expands into a gas when in use.

Pneumatic systems are usually simpler to design and control than hydraulic systems. They also tend to be more reliable, compressible gas can absorb shocks reducing damage to machinery. Pneumatic systems are also safer, the gasses used are nonflammable and the systems can typically fail-safe.

Hydraulic systems have their own advantages. They are more efficient, precisely because gasses tend to absorb some energy while liquids transmit all of their applied load. There's no need to bleed off excess pressure when disconnecting equipment from a hydraulic system. But their biggest advantage is their carrying load. Pneumatic systems can support about 80 - 100 psi. Hydraulic systems typically support 1,000 - 5,000 psi and can be designed up to 10,000 psi.

Now let's consider a simple hydraulic/pneumatic system:

The various components of this system are connected by conductors. In fluid systems a conductor is simply a pipe or hose that contains and transmits the fluid. Conductors must be rated for the pressure that the working fluid is intended to be transmitted at.

At the start of the system is a pump or compressor. These two devices serve the same function, they increase the pressure of the fluid. Pumps add pressure to a liquid, while compressors add pressure to a gas.

Working fluid goes from the pump into an accumulator, a tank designed to hold pressurized gas. The accumulator stores the fluid as the pump builds up pressure. From the accumulator the fluid passes through a check valve. If the pressure is correct the check valve allows fluid to pass to the loads, if the pressure grows to high the check valve sends fluid straight to the reservoir.

Loads are devices attached to the hydraulic system that do some work using the fluid pressure. The fluid expends its pressure doing work and the now low pressure fluid passes into the reservoir.

The reservoir is a second, low pressure, holding tank that collects used fluid from the loads. Here the working fluid is stored until it again passes through the pump and into the hydraulic system again.

Pneumatic systems using air don't have a reservoir attached. The reservoir in this case is the atmosphere. Air is released by the load into the atmosphere and the compressor pulls air straight from its surroundings.

Many systems are precharged, meaning that the accumulator is already pressurized. In this kind of system there is no pump or reservoir, spent working fluid is vented overboard. Such a system is much lighter and simpler than a full system with compressor, however they have a very limited operating life. When the pressure of the accumulator is spent the system is no longer any use. Many spacecraft use precharged systems.

Now let's take a closer look at the devices in a fluid system. First consider the devices we already saw in the simple pneumatic system above. It is composed of two pressure vessels, the reservoir and the accumulator; several valves; and a pump or compressor.

Pressure vessels are tanks designed to contain a fluid under pressure. They are rated based on their wall thickness, which determines how much pressure they can hold. Readily available tanks are also given in terms of standard sizes. One design that increases the strength, and so the pressure rating, of a tank is a composite overwrap vessel. In this design a metal liner is surrounded with adhesive and a layer of composite fiber. This gives the tank additional strength with little increase in mass.

Valves are simple devices that either block fluid flow or divert it when closed. They come in two types. Type 1 valves remain in the position they were set to until they are again changed. Type 2 valves are classifies as either normally open or normally closed. Type 2 valves return to their normal position when force is removed. Valves can also be one-way, allowing fluid to pass in one direction freely, but blocking all passage backwards.

Pumps and compressors take work from some outside source and convert it into fluid pressure. The most common pumps used in fluid systems use turbomachinery, that is spinning parts, to push fluid. The simplest example, there is probably one in the room, is a fan. The fan's blades create an aerodynamic force which pushes on the air. There are many different configurations of turbo- pumps and compressors. Below is a gas compressor:

Not all pumps are turbomachines, however. A simple bicycle pump uses a much simpler system. There are two one-way valves, one allowing air in from the environment and one allowing it out through the hose. Pulling on the piston creates a vacuum which draws in air, pushing it down forces the air out.

There is another type of turbomachine that does the opposite job. A turbine uses fluid pressure to produce work. Fluid passes through a sequence of turbine blades, imparting a force to them. This causes a shaft to spin, which draws power from the fluid. Energy from the fluid (which existed as pressure) is given to the shaft (as rotation) allowing us to use the fluid to produce useful power.

Pistons also remove pressure from the fluid and convert it into power. In a piston pressure forces the plunger to move out. The plunger is then pulled back, forcing the working fluid back out. A full motion of the plunger up or down is called a single stroke.

A two-stroke piston has two inlets, pressurized fluid pushes the cylinder out, expending its pressure. Then pressurized fluid enters through the other inlet pushing the piston back in and forcing the spent working fluid on the other side of the plunger out. This repeats. Other designs have two or more pistons attached to a single rotating wheel, when one pushes out the wheel pushes the other back in.

In a hydraulic system turbines are used to produce rotation. Pistons are used to produce a back and forth motion. Pistons can produce rotation by attaching them to a crank shaft they can also produce rotation, as is done in care engines. However turbines are far more efficient for pneumatic applications.

Heat exchangers add or remove heat from the working fluid. Fluid passes through a series of thermal conductors, usually metal, that are connected to a source of heat or a cold sink. Heat exchangers attached to points hotter than the fluid entering are called high temperature reservoirs. Heat exchangers connected to points colder than the fluid are low temperature reservoirs. Heat exchangers add or remove energy from the flow in the form of heat.

As we discussed when looking at rockets fluid devices called nozzles convert pressure into velocity. Another device, called a diffuser, does the opposite job. Diffusers slow down the working fluid in order to increase its pressure. These two devices are very similar in shape and design. For subsonic flow (which liquids must be and pneumatic systems generally are) a nozzle narrows and a diffuser expands.

Throttles also obstruct flow. At the throttle flow suddenly narrows, drastically reducing pressure and trading it for velocity, unlike a nozzle where this change is smooth. Throttles function much like valves, in that they open and close allowing some flow through.

We've looked at fluid systems and devices in a very general sense so far. But why are we even looking at them? What are they used for on spacecraft that makes them worth considering? Well, before looking at hydraulics on spacecraft lets consider two other kinds of fluid systems that we've already looked at.

Consider the rocket systems we saw before. Rockets are fundamentally a fluid system. The working fluid is the propellant. The combustion chamber releases pressurized working fluid through a nozzle, which does work by converting pressure into velocity and causing a transfer of momentum.

Liquid and hybrid rockets have a complex fluid system leading into the combustion chamber. Cold propellant is sent through pumps into the combustion chamber. In regenerative systems it passes though a heat exchanger, gaining energy from it. The entire propulsion system is a fluid system.

Many thermal control systems are also fluid systems. In this case the working fluid is coolant. It passes through heat exchangers, taking heat away from systems that produce it. The fluid is compressed and is forced to give up that heat, then passes through the system again.

Hydraulic systems are used on spacecraft because of their very high energy density. Similar electrical systems would be needlessly bulky. Below is a graphic of the hydraulic systems used aboard the Space Shuttle.

In general hydraulic systems are used any time a great deal of force is needed in a confined area. Hydraulics are used for thrust vector control, shifting the orientation of heavy engines that are mounted on gimbals. They move aerosurfaces, flaps and rudders that control the motion of launch vehicles against immense aerodynamic loads.

Hydraulic systems are also used to open propellant valves on large vehicles. The amount of fluid and pressure involved in large engines is simply too great for a reasonably sized electric valve to be used. In a sense the hydraulic valve amplifies the strength of the electric valve which is used to activate it.

It is common for engineers to keep a project notebook containing all work and calculations. I present mine.

Showing posts with label Spacecraft Systems. Show all posts

Showing posts with label Spacecraft Systems. Show all posts

September 1, 2013

August 7, 2013

Pyrotechnics

Pyrotechnic devices, or explosive ordnance, are used on spacecraft for many applications. They have high energy density and are compact, easily stored, and controllable. However they are only used reluctantly. When another option is available generally it will be selected over pyros.

Pyros are single-use devices, once set-off there is no retrieving them and the system cannot be reset. Pyros can only be used for a component that begins in one configuration and then changes to another and remains that way for the rest of the flight.

They produce very short, impulsive loads. Despite their high energy density all that energy is expended at once. Pyros don't release their energy in a controlled fashion and controlling the energy release involves additional structure and engineering.

A pyrotechnic device cannot be functionally tested, there is no way to be certain it works until it is used. There are very few tests that can be done to ensure a charge functions before installing it. Reliability of pyros is based on qualification. If we get a box of 100 then we set of 20 of them. If all of them go off we assume there's a good chance that the next one will when we use it.

If something does go wrong with a pyro during flight there's very little that can be done about it. Failures can and do happen, and when they do the vehicle is already off the ground. Redundancy can be used to mitigate failures, so that if one pyro doesn't go off another can accomplish the same job.

Pyro usage falls into three broad categories: operational, flight termination, and emergency use. Operational devices are used as a standard part of the flight plan. Emergency use devices are activated during contingencies, to regain control of the vehicle or attempt to salvage some critical system (like the crew). Flight termination devices are used to safely abort failed flights. An aborted flight is destroyed and/or sent into the ocean, to reduce the damage it does as much as possible.

Pyros are classified into two categories: category A, hazardous, and category B, nonhazardous. Category B devices could go off in your hand without causing any injury.

With any explosive device we have two chief concerns: inadvertent firing and nonfiring. Either of these could result in mission failure, since each step of the mission is time dependent. Both are also serious range safety concerns. An early firing could happen while technicians are on the range working. A nonfire means a primed explosive is still sitting on the range, and no one knows when it might finally go off.

To minimize risk a number of requirements are in place for pyros. They are always installed as late as possible during the assembly process. After installation inhibitors are put in place to prevent the devices from going off, and are not removed until just before launch.

Once the pyros are in place radio broadcast at the range is limited so that the radio power at any device is less than 20dB under the no-fire power. Electromagnetic waves can induce a current in a wire, so radio power must be kept low enough that the induced power is always below the lowest level that the devices will fire at.

During installation there is full radio silence on the range. No other operations take place during pyro installation and all range personnel wear flame retardant, nonstatic coveralls. All equipment and personnel must be grounded. Pyros have faraday caps, metal covers that provide a voltage path around the charge. All lines are checked for stray voltage prior to installation. There must be a clear area of at least 10ft around any work with pyros. Humidity must be at least 35% and there cannot be a storm within 5mi. All these precautions are taken to ensure no stray spark accidentally triggers any explosive device during installation.

Pyrotechnic systems are designed to be completely separate from all other systems. A pyro system has shielded circuits with a single common ground. All pyros are built with metal connectors that cannot mismate. The pyro system consists of the following, separate and independent, systems:

That gives you a rough idea of just how serious the safety concerns are when handling and installing pyrotechnic devices. Now we'll look at a few of the ways they are used.

Initiators are used to trigger another device. They can be used to ignite a solid rocket motor or to set off another pyrotechnic device. The NASA Standard Initiator (NSI-1) is seen below, connected to the NSI-Detonator. The detonator amplifies the explosive force of the standard initiator.

Frangible nuts are a category B ordnance used to uncouple structures. They are ordinary nuts with breaking points added. These breaking points are stuffed with explosives, so that when the pyro is triggered the nut breaks along the existing failure line.

Separation bolts serve a similar function. They are hollow, with explosive charge built in and a designed failure point. When the explosive goes off it pushes a pin, which breaks the bolt at the defined point.

Pyrotechnic linear actuators push a rod out. The rod is contained in a hollow chamber with a small explosive charge. When the charge goes off the pin is pushed out by the force. Spring-loaded pins keep the rod in place once extended.

Pin pullers do the opposite job, they retract a rod. In this case the rod ends in a plunger, with the explosive charge between it and the wall. The explosive pushed the plunger back and the pin withdraws.

Pyrotechnic valves switch from open to close, or closed to open, once. Normally open valves switch to closed, by pushing a plug into the flow. Normally closed valves have a plug with an opening above in the flow, it is pushed so that the opening allows fluid through once activated. Both of these pictures are normally closed valves

Shaped linear charges hold an explosive in a metal container, which expands when the explosive goes off. Mild detonating chord contains a linear core of explosive material contained in a metal sheath. Confined detonating fuse uses a combination of fiberglass outer sheath, rayon middle sheath, and lead inner sheath with layers of vinyl between. CDF contains an explosion once the linear charge goes off.

Super*Zip is another method of severance. Two sheet metal faces surround a core structure. At points the core is replaced with CDF, as the CDF goes off its outer sheath expands. This pushes the two plates out until they break, separating the structure. It gets its name because it resembles a zipper being unzipped.

Pyros are single-use devices, once set-off there is no retrieving them and the system cannot be reset. Pyros can only be used for a component that begins in one configuration and then changes to another and remains that way for the rest of the flight.

They produce very short, impulsive loads. Despite their high energy density all that energy is expended at once. Pyros don't release their energy in a controlled fashion and controlling the energy release involves additional structure and engineering.

A pyrotechnic device cannot be functionally tested, there is no way to be certain it works until it is used. There are very few tests that can be done to ensure a charge functions before installing it. Reliability of pyros is based on qualification. If we get a box of 100 then we set of 20 of them. If all of them go off we assume there's a good chance that the next one will when we use it.

If something does go wrong with a pyro during flight there's very little that can be done about it. Failures can and do happen, and when they do the vehicle is already off the ground. Redundancy can be used to mitigate failures, so that if one pyro doesn't go off another can accomplish the same job.

Pyro usage falls into three broad categories: operational, flight termination, and emergency use. Operational devices are used as a standard part of the flight plan. Emergency use devices are activated during contingencies, to regain control of the vehicle or attempt to salvage some critical system (like the crew). Flight termination devices are used to safely abort failed flights. An aborted flight is destroyed and/or sent into the ocean, to reduce the damage it does as much as possible.

Pyros are classified into two categories: category A, hazardous, and category B, nonhazardous. Category B devices could go off in your hand without causing any injury.

With any explosive device we have two chief concerns: inadvertent firing and nonfiring. Either of these could result in mission failure, since each step of the mission is time dependent. Both are also serious range safety concerns. An early firing could happen while technicians are on the range working. A nonfire means a primed explosive is still sitting on the range, and no one knows when it might finally go off.

To minimize risk a number of requirements are in place for pyros. They are always installed as late as possible during the assembly process. After installation inhibitors are put in place to prevent the devices from going off, and are not removed until just before launch.

Once the pyros are in place radio broadcast at the range is limited so that the radio power at any device is less than 20dB under the no-fire power. Electromagnetic waves can induce a current in a wire, so radio power must be kept low enough that the induced power is always below the lowest level that the devices will fire at.

During installation there is full radio silence on the range. No other operations take place during pyro installation and all range personnel wear flame retardant, nonstatic coveralls. All equipment and personnel must be grounded. Pyros have faraday caps, metal covers that provide a voltage path around the charge. All lines are checked for stray voltage prior to installation. There must be a clear area of at least 10ft around any work with pyros. Humidity must be at least 35% and there cannot be a storm within 5mi. All these precautions are taken to ensure no stray spark accidentally triggers any explosive device during installation.

Pyrotechnic systems are designed to be completely separate from all other systems. A pyro system has shielded circuits with a single common ground. All pyros are built with metal connectors that cannot mismate. The pyro system consists of the following, separate and independent, systems:

- power source - a dedicated battery or capacitor independent of the main power bus.

- firing circuit - circuit that connects the initiating device, or detonator, to the power source. FIRE and ARM circuits are required to be separate, so that if either is accidentally triggered there is no ignition.

- control circuit - activates and deactivates the safety devices

- monitor circuit - monitors the firing circuit for stray voltage. This must be completely independent of the control and firing circuits.

That gives you a rough idea of just how serious the safety concerns are when handling and installing pyrotechnic devices. Now we'll look at a few of the ways they are used.

Initiators are used to trigger another device. They can be used to ignite a solid rocket motor or to set off another pyrotechnic device. The NASA Standard Initiator (NSI-1) is seen below, connected to the NSI-Detonator. The detonator amplifies the explosive force of the standard initiator.

Frangible nuts are a category B ordnance used to uncouple structures. They are ordinary nuts with breaking points added. These breaking points are stuffed with explosives, so that when the pyro is triggered the nut breaks along the existing failure line.

Separation bolts serve a similar function. They are hollow, with explosive charge built in and a designed failure point. When the explosive goes off it pushes a pin, which breaks the bolt at the defined point.

Pyrotechnic linear actuators push a rod out. The rod is contained in a hollow chamber with a small explosive charge. When the charge goes off the pin is pushed out by the force. Spring-loaded pins keep the rod in place once extended.

Pin pullers do the opposite job, they retract a rod. In this case the rod ends in a plunger, with the explosive charge between it and the wall. The explosive pushed the plunger back and the pin withdraws.

Pyrotechnic valves switch from open to close, or closed to open, once. Normally open valves switch to closed, by pushing a plug into the flow. Normally closed valves have a plug with an opening above in the flow, it is pushed so that the opening allows fluid through once activated. Both of these pictures are normally closed valves

Shaped linear charges hold an explosive in a metal container, which expands when the explosive goes off. Mild detonating chord contains a linear core of explosive material contained in a metal sheath. Confined detonating fuse uses a combination of fiberglass outer sheath, rayon middle sheath, and lead inner sheath with layers of vinyl between. CDF contains an explosion once the linear charge goes off.

Sections:

Lessons,

Spacecraft Systems

August 1, 2013

Structures

Before we look at how a spacecraft's structure is put together we need to consider how structures are built at all. Most structures are built in one of two ways: they use a frame, a skeleton of members to give it shape and strength, or they use load bearing walls, in which the entire structure's face supports it. Most spacecraft structures use a combination of the two.

A load is a force which a member is subjected to. There are three forms of simple loads: tension, compression, and shear. Tension loads pull against the member, compression loads push on it. Shear loads push or pull two sides of the member in opposite directions. Materials are generally stronger against compression and tension than they are against shear.

Imagine a block of wood supporting a load above it. Naturally we know that a wider block can support more weight. But all blocks of wood can support the same amount of stress. Stress is defined as the load divided by the cross-sectional area of the member supporting it, the width and thickness of the block. While a block with a larger area can support more load than a thinner one they can both support the same amount of stress.

When a member is stressed it changes its dimensions. Think about a rubber band, when you pull on it it gets longer and thinner. That's because there's still the same amount of material there was before. So if we compress an object it should get wider and shorter. The change in the length of a member under stress is called the strain. Strain is defined as the change in length of the object divided by the original length:

When subjected to the same stress a given material will always experience the same strain. This is a material constant, something that is the same for this material no matter the situation. The property that relates stress and strain in a material is called Young's modulus (or the elastic modulus):

Most materials are elastic for a while, when deformed they spring back after the load is removed. After a certain amount of stress, called the yield strength, they are no longer elastic and Young's modulus isn't useful anymore. After the yield stress they are plastic, their deformation is permanent. Eventually enough stress is applied that they break entirely, called the ultimate strength. We usually don't want a material to yield, since we want it to keep whatever shape we put it in, so we need to make sure that members aren't subjected to loads above their yield strength.

In the elastic region stress and strain are related by the modulus. After the material yields it enters the plastic region, where force simply goes into deforming it. Eventually it deforms so much that it breaks. Materials with a large plastic region are called ductile; we can shape them and they remain in their new shape and will resist changing from it. Materials with a small, or no, plastic region are called brittle; once they yield they break. Counter-intuitive as it may seem a rubber band is brittle, it has no plastic region and breaks as soon as it is over-stretched.

Many common materials have the same properties in all three dimensions: x, y, and z. These materials are called isotropic. Some materials do not have the same strength or stiffness in all directions, however, and are called non-isotropic. An everyday example of a non-isotropic material is wood. Wood is much stronger in the grain direction than against the grain, this is because the grain fibers are stronger than the sap that holds them together. Consider also plywood, which is composed of thin sheets of wood glued together. The glue is its weakest point, so the plywood has different properties in all three dimensions: the fiber is stronger than the sap, which is stronger than the glue. Modern fiber reinforced composites are similar. They are stronger in the grain direction than any other, and the matrix holding different plies together is the weakest point.

As simple as the three basic load conditions are, most materials won't actually fail in shear or compression. Under most situations when a material is subjected to a shear load it doesn't actually shear apart, it bends. Bending occurs when part of a material is pushed in one direction and the rest is pushed in the other. Usually shear happens when these two forces are very close together.

Observe that when the material bends its top half is in compression and the bottom half is in tension. The bending stress in both is the same, but it is in opposite directions. In the middle, the neutral axis, there is no stress. It goes from negative that value on top to zero in the middle to positive on the bottom. The bending stress depends on distance from the neutral axis, the further away from it the higher the stress.

This is the reason for I-beams. Since there is little stress in the center there is no need for material there. Most of the material is at the top and bottom, where the stress is highest.

Now, consider again the wood column with a load on top. Will it actually get thicker? Usually not unless it is already very thick, most thin member will buckle when subjected to compression loads. Buckling occurs when part of the material bows out. It is like bending, except that the load pushes in along the axis.

We need to be concerned with both buckling and compressive failure when loading a column in compression. Just as we need to be concerned with both shear and bending failure when subjected it to a shear load. Bending and buckling depend on the moment of inertia of the structure, while compression and shear depend on the area. This means that while the simple load cases (compression and shear) only depend on how much material there is, bending and buckling depend on how it is arranged.

Before we observed that elastic materials spring back into shape when deformed. Picture a spring, when you push it down it bounces back. But before it gets back to where it started it bounces back and forth for a while. Materials that have deformed act exactly the same way, when they bounce back they vibrate slightly for a while. All objects have a range of natural frequencies that they vibrate at when subjected to a force. The lowest of these is called the fundamental frequency, it is the one which the object is most likely to vibrate at. Think about a guitar string. When you pluck the string it vibrates. Shorten the string and the pitch gets higher, thicken the string and it gets lower:

The kinds of failure we looked at before come from static loads. Static loads do not change with time. There are also dynamic loads, which do change with time. Dynamic loads can be transients, brief or rapidly changing loads like a ramp up/down or an impact, or cyclic. Cyclic loads repeat themselves. They subject the member to a force that is time varying, with some maximum, minimum, and average values, and repeats with some frequency:

Ordinarily we would only worry about the peak stress here being higher than the yield stress of a member. However if the frequency of the stress is the same as the fundamental frequency of the member a situation called resonance occurs. In resonance each time the material gets to the peak of its displacement it is pushed back by the force, pushing it a little further each time. Picture a kid on a swing. By pumping his legs just as gets to the back of his swing he can push the next swing a little further. In a material this pushes the material's deformation further and further each cycle, until it fails. Resonance can cause even small loads to build up to catastrophic displacements. For an excellent reference consider the Mythbusters' attempts to recreate Nikola Tesla's claims to have invented an earthquake machine.

So that's what loads do to a member in a structure. But where do the loads come from? A vehicle in space experiences forces from several sources:

A spacecraft is composed of two forms of structure. Primary structure gives the spacecraft its shape and holds all of the systems together. Secondary structure provides support and mounting for the various systems and subsystems. The secondary structure transmits loads from the systems to the primary structure and reduces loads going to systems.

Forces are carried by members in a structure and transmitted through it. In a load bearing wall the wall carries forces through it, so that most of the wall is under the same load. In a frame supported system each member in the frame carries a force through its length to the joint where it is connected to other members. Consider the simple trusses below:

Each member caries a force through its length. So a horizontal member carries horizontal loads, a vertical member carries vertical loads, and a diagonal member carries some vertical and some horizontal load.

On the ground our goal is to transmit the loads through the structure to the ground. Each member carries the load in whichever direction it can until we get to the grounding points. The ground provides the reaction force, it pushes back in the opposite direction so that our structure doesn't move.

In space there is no ground to bring the load to. If the entire primary structure is subjected to the same force then the structure will move. To prevent the spacecraft from moving we must either cancel or dampen the force. Cancelling a force means applying another force of the same strength in the opposite direction. Like the torque wrench example we talked about back in attitude control, the two up and downward forces cancel so the head doesn't move up or down.

Damping reduces or prevents motion. Damping is usually caused by friction. It happens inside all materials, internal friction happens when a material vibrates. As it does the vibration also slows until it eventually stops. Any time the structure deforms some of the energy that might have made it move is absorbed instead.

Viscous damping happens when a solid object move through a fluid, like air. Though there is no air resistance in space we can add viscous dampers to reduce motion of components that should remain fixed. The simplest viscous damper is a plunger in a piston of fluid, which resists the motion of the plunger.

Shock absorbers and isolators are in essence simply springs with very high damping. The spring absorbs the shock by compressing or expanding. The damper prevents it from springing back quickly, so the load is transferred up very slowly. Much of the load is also absorbed by the damper so there is less motion.

Mass also resists motion on its own, through inertia. So when we apply a load to a structure there are three places it can go: into deforming material, into friction, or into accelerating the structure. How much force is used deforming it depends on how far it is pushed, how much is spent against friction depends on how fast it moves, the rest tries to accelerate it:

So long as each member can support the load it is subjected to then it will act like a combination of a spring and a damper. It will also try to move, but be stopped by the next member in the frame, which will experience whatever force wasn't absorbed. This continues through the whole structure. Eventually every member is under some stress. When the load is removed everything springs back to how it was. Whether or not the whole vehicle moves depends on whether every member is trying to accelerate in the same direction and if there is enough force to overcome the tendency of materials to act as springs.

A load is a force which a member is subjected to. There are three forms of simple loads: tension, compression, and shear. Tension loads pull against the member, compression loads push on it. Shear loads push or pull two sides of the member in opposite directions. Materials are generally stronger against compression and tension than they are against shear.

Imagine a block of wood supporting a load above it. Naturally we know that a wider block can support more weight. But all blocks of wood can support the same amount of stress. Stress is defined as the load divided by the cross-sectional area of the member supporting it, the width and thickness of the block. While a block with a larger area can support more load than a thinner one they can both support the same amount of stress.

When a member is stressed it changes its dimensions. Think about a rubber band, when you pull on it it gets longer and thinner. That's because there's still the same amount of material there was before. So if we compress an object it should get wider and shorter. The change in the length of a member under stress is called the strain. Strain is defined as the change in length of the object divided by the original length:

When subjected to the same stress a given material will always experience the same strain. This is a material constant, something that is the same for this material no matter the situation. The property that relates stress and strain in a material is called Young's modulus (or the elastic modulus):

Most materials are elastic for a while, when deformed they spring back after the load is removed. After a certain amount of stress, called the yield strength, they are no longer elastic and Young's modulus isn't useful anymore. After the yield stress they are plastic, their deformation is permanent. Eventually enough stress is applied that they break entirely, called the ultimate strength. We usually don't want a material to yield, since we want it to keep whatever shape we put it in, so we need to make sure that members aren't subjected to loads above their yield strength.

In the elastic region stress and strain are related by the modulus. After the material yields it enters the plastic region, where force simply goes into deforming it. Eventually it deforms so much that it breaks. Materials with a large plastic region are called ductile; we can shape them and they remain in their new shape and will resist changing from it. Materials with a small, or no, plastic region are called brittle; once they yield they break. Counter-intuitive as it may seem a rubber band is brittle, it has no plastic region and breaks as soon as it is over-stretched.

Many common materials have the same properties in all three dimensions: x, y, and z. These materials are called isotropic. Some materials do not have the same strength or stiffness in all directions, however, and are called non-isotropic. An everyday example of a non-isotropic material is wood. Wood is much stronger in the grain direction than against the grain, this is because the grain fibers are stronger than the sap that holds them together. Consider also plywood, which is composed of thin sheets of wood glued together. The glue is its weakest point, so the plywood has different properties in all three dimensions: the fiber is stronger than the sap, which is stronger than the glue. Modern fiber reinforced composites are similar. They are stronger in the grain direction than any other, and the matrix holding different plies together is the weakest point.

As simple as the three basic load conditions are, most materials won't actually fail in shear or compression. Under most situations when a material is subjected to a shear load it doesn't actually shear apart, it bends. Bending occurs when part of a material is pushed in one direction and the rest is pushed in the other. Usually shear happens when these two forces are very close together.

Observe that when the material bends its top half is in compression and the bottom half is in tension. The bending stress in both is the same, but it is in opposite directions. In the middle, the neutral axis, there is no stress. It goes from negative that value on top to zero in the middle to positive on the bottom. The bending stress depends on distance from the neutral axis, the further away from it the higher the stress.

This is the reason for I-beams. Since there is little stress in the center there is no need for material there. Most of the material is at the top and bottom, where the stress is highest.

Now, consider again the wood column with a load on top. Will it actually get thicker? Usually not unless it is already very thick, most thin member will buckle when subjected to compression loads. Buckling occurs when part of the material bows out. It is like bending, except that the load pushes in along the axis.

We need to be concerned with both buckling and compressive failure when loading a column in compression. Just as we need to be concerned with both shear and bending failure when subjected it to a shear load. Bending and buckling depend on the moment of inertia of the structure, while compression and shear depend on the area. This means that while the simple load cases (compression and shear) only depend on how much material there is, bending and buckling depend on how it is arranged.

Before we observed that elastic materials spring back into shape when deformed. Picture a spring, when you push it down it bounces back. But before it gets back to where it started it bounces back and forth for a while. Materials that have deformed act exactly the same way, when they bounce back they vibrate slightly for a while. All objects have a range of natural frequencies that they vibrate at when subjected to a force. The lowest of these is called the fundamental frequency, it is the one which the object is most likely to vibrate at. Think about a guitar string. When you pluck the string it vibrates. Shorten the string and the pitch gets higher, thicken the string and it gets lower:

The kinds of failure we looked at before come from static loads. Static loads do not change with time. There are also dynamic loads, which do change with time. Dynamic loads can be transients, brief or rapidly changing loads like a ramp up/down or an impact, or cyclic. Cyclic loads repeat themselves. They subject the member to a force that is time varying, with some maximum, minimum, and average values, and repeats with some frequency:

Ordinarily we would only worry about the peak stress here being higher than the yield stress of a member. However if the frequency of the stress is the same as the fundamental frequency of the member a situation called resonance occurs. In resonance each time the material gets to the peak of its displacement it is pushed back by the force, pushing it a little further each time. Picture a kid on a swing. By pumping his legs just as gets to the back of his swing he can push the next swing a little further. In a material this pushes the material's deformation further and further each cycle, until it fails. Resonance can cause even small loads to build up to catastrophic displacements. For an excellent reference consider the Mythbusters' attempts to recreate Nikola Tesla's claims to have invented an earthquake machine.

So that's what loads do to a member in a structure. But where do the loads come from? A vehicle in space experiences forces from several sources:

- propulsion - thrust is generally a static load applied by the spacecraft's engines. Engine sputter can also cause small transient loads and the engine itself can vibrate causing small cyclic loads.

- deployment - extending booms or opening apertures creates transient loads on the vehicle.

- thermal - when a material heats it expands, when it cools it shrinks back, causing thermal strain. If it's being held in place then a thermal stress results from holding it back. This can be a static load if the material stays at the new temperature, cyclic if it heats and cools (like a spacecraft moving in and out of sunlight), or transient if the heating is brief.

- internal mechanics - mechanical systems by definition move, they subject some component to force. They are also subjected to some force, as is whatever they are mounted to.

- thrust - launch thrust is much higher than the small thrust values used once in orbit. Payload fairings are designed to lessen the g-loading payloads are subjected to, but cannot completely eliminate the force.

- aerodynamic forces - as the launch vehicle moves through the atmosphere it is buffeted by winds. This is generally a transient load, gusts blow briefly, creating high force for a brief time. By design little of this load reaches the payload.

- acoustic and vibration - the entire vehicle shakes during launch and produces extremely powerful sound waves. These in turn cause the vehicle to vibrate.

- staging, separation, and injection - transient loads caused by the launch vehicle discarding unneeded parts during flight.

A spacecraft is composed of two forms of structure. Primary structure gives the spacecraft its shape and holds all of the systems together. Secondary structure provides support and mounting for the various systems and subsystems. The secondary structure transmits loads from the systems to the primary structure and reduces loads going to systems.

Forces are carried by members in a structure and transmitted through it. In a load bearing wall the wall carries forces through it, so that most of the wall is under the same load. In a frame supported system each member in the frame carries a force through its length to the joint where it is connected to other members. Consider the simple trusses below:

Each member caries a force through its length. So a horizontal member carries horizontal loads, a vertical member carries vertical loads, and a diagonal member carries some vertical and some horizontal load.

On the ground our goal is to transmit the loads through the structure to the ground. Each member carries the load in whichever direction it can until we get to the grounding points. The ground provides the reaction force, it pushes back in the opposite direction so that our structure doesn't move.

In space there is no ground to bring the load to. If the entire primary structure is subjected to the same force then the structure will move. To prevent the spacecraft from moving we must either cancel or dampen the force. Cancelling a force means applying another force of the same strength in the opposite direction. Like the torque wrench example we talked about back in attitude control, the two up and downward forces cancel so the head doesn't move up or down.

Damping reduces or prevents motion. Damping is usually caused by friction. It happens inside all materials, internal friction happens when a material vibrates. As it does the vibration also slows until it eventually stops. Any time the structure deforms some of the energy that might have made it move is absorbed instead.

Viscous damping happens when a solid object move through a fluid, like air. Though there is no air resistance in space we can add viscous dampers to reduce motion of components that should remain fixed. The simplest viscous damper is a plunger in a piston of fluid, which resists the motion of the plunger.

Shock absorbers and isolators are in essence simply springs with very high damping. The spring absorbs the shock by compressing or expanding. The damper prevents it from springing back quickly, so the load is transferred up very slowly. Much of the load is also absorbed by the damper so there is less motion.

Mass also resists motion on its own, through inertia. So when we apply a load to a structure there are three places it can go: into deforming material, into friction, or into accelerating the structure. How much force is used deforming it depends on how far it is pushed, how much is spent against friction depends on how fast it moves, the rest tries to accelerate it:

So long as each member can support the load it is subjected to then it will act like a combination of a spring and a damper. It will also try to move, but be stopped by the next member in the frame, which will experience whatever force wasn't absorbed. This continues through the whole structure. Eventually every member is under some stress. When the load is removed everything springs back to how it was. Whether or not the whole vehicle moves depends on whether every member is trying to accelerate in the same direction and if there is enough force to overcome the tendency of materials to act as springs.

Sections:

Lessons,

Spacecraft Systems

July 18, 2013

Environmental Control

Every system and component on a spacecraft has its own range of operating temperatures. Outside of this range it either breaks or simply can't work properly. The duty of the thermal control system is to keep all the components within their allowable operating range. An earth orbiting spacecraft can be subjected to skin temperatures from -270 to 2,000 degrees centigrade. No component on board can handle that. Reasonable operating ranges for spacecraft components:

Temperature is a measure of how much energy is stored in a substance. The atoms making up a substance are constantly in motion, in fluid they move around each other freely, in a solid they vibrate in place. Temperature measures how much they move around, how quickly they flow past one another or vibrate.

Heat is a means of transferring that energy. When something cools it releases heat it gives up some of that energy it contained. When a substance is heated heat enters it and the motion increases.

An object can produce and release heat at the same time. If it releases more heat than it produces then it cools, and temperature goes down. If more heat comes in, or is produced, than leaves then the temperature goes up. When the two are exactly equal the temperature remains constant, and we say the object is in thermal equilibrium.

That's where we want to keep our spacecraft systems, holding steady at their operating temperatures. In addition to producing heat inside an object, heat can be transferred in three different ways.

Conduction occurs inside a substance. The motion of atoms causes them to collide with each other, spreading their energy. You can see this very clearly if you try to grab a metal bot handle. Metals are good heat conductors, they transfer their energy easily. Conduction occurs when one part of an object is hotter than another and stops when the whole object is the same temperature. Conductivity is the measure of how easily an object transfers heat, heat transfer rate depends on that and the difference in temperature along the length of an object. For a rod with a cross-section A:

Convection occurs when a fluid passes over a solid wall. At the surface conduction happens at a tiny scale between the two, and also occurs in each substance away from that surface. We call the whole effect together convection. Convection depends on the temperature of the fluid and the wall, as well as the transfer constant between them:

Convection also happens inside a fluid when heat in one part of the fluid causes it to move. Convection causes hot fluid to move up, or away from walls, because it is less dense and less viscous.

Radiation occurs in all substances, solid or fluid. Atoms in a substance have energy from their temperature. In addition to motion some of this energy excites the atom, changes the energy level of its electrons. If the energy is so great they leave the atom it's called ionizing the atom and if that happens to the whole substance it becomes a plasma. But more often the electrons are excited for a short time and then fall back to where they were. When that happens they release electromagnetic radiation, or a photon. At higher temperatures the energy of the photon emitted increases. At first its invisible infra-red light, most heat stays here. But as the heat increases it can raise to the visible spectrum. If you've ever seen a piece of iron or steel in a forge or furnace you've seen this effect. Red hot steel is hot enough that it radiates in the visible red spectrum. As it becomes hotter it starts releasing yellow light in addition to the red, so it looks orange. Even hotter and it releases higher frequencies too, which together makes it look white. Iron is literally glowing hot, it's producing light, when it is red or white hot.

Radiation output of a substance depends on its surface area and temperature, obviously. These are related to the radiative heat output by the Stefan-Boltzmann Constant (the Greek letter sigma) and a material property known as the emissivity (Greek letter epsilon). Emissivity is the ratio of how much radiation a substance could put out, to how much it actually puts out. It ranges from zero to one. An object with an emissivity of one is called a black-body, a perfect radiator often used in physics as an ideal model. At zero the body doesn't radiate at all, which also doesn't happen in real life, though some objects come close to one extreme or the other.

Bodies don't just emit heat radiation, they also absorb it. The ratio of how much heat comes in to how much heat the substance absorbs is the absorptivity:

Besides absorbing the radiation the substance can also reflect some back into space and transmit some through it. The ratio of how much transmitted through is called transmissivity, the ratio of how much is reflected is called reflectivity.

Incoming can only do these three things, be absorbed by the material, reflected back by it, or transmitted through it. So all three terms must add up to one:

A spacecraft usually isn't in contact with any other solid object, or moving through a fluid. The only means of heat transfer between the spacecraft and its environment is radiative. Environmental heat sources for a spacecraft in low earth orbit begin with the sun. Direct sunlight is the greatest source of heat, averaging around 1358 watts per square meter of skin exposed to it. Some sunlight is indirect. When sunlight comes to earth some is absorbed and some reflected (it's too thick to transmit light well) earth's albedo reflects that light. The amount of heat coming from earth's albedo varies drastically depending on position, a value used to design for is about 407 watts per square meter. Finally some of the heat from earth has nothing to do with the sun. Earth, after all, has temperature and radiates like any other body. For a spacecraft in LEO earthshine accounts for 237 watts per square meter. Unlike direct sunlight or albedo this is constant, earthshine doesn't depend on position. The side facing earth always experiences this, while direct sunlight ceases whenever the spacecraft is eclipsed by the earth. During eclipse one side is subjected to earthshine and the other has no incident heat.

So we need some method of limiting, or at least evening out, the environmental heating a spacecraft is exposed to. We call means of controlling heat into the spacecraft external thermal control.

One method is to simply prevent any one side from facing the source of heat for too long. When the spacecraft is on the day side of the earth one side is facing the sun at over 1300 watts per square meter, the other side is exposed to less than a fifth from earthshine. By simply rotating the spacecraft in roll which side is constantly changing. This method, popularly known as the barbecue roll. It takes time for the spacecraft to heat up when exposed to the sun, rotating the spacecraft prevents any one part from getting that time. As it's facing a colder direction is is radiating that heat out.

A barbecue roll can slow the skin of the spacecraft heating up. But we still worry about heat passing through the skin, to the more heat sensitive components. Temperature sensitive components are covered by insulation to prevent heat from getting to them. Multi-layer insulation (MLI) is the common method. MLI is, as the name implies, composed of many thin layers of insulation protecting the spacecraft, each with low transmissivity. Multiple layers are used because the radiation between layers is much slower than the conduction through a single thick layer. Inner layers usually use Mylar and Kapton sheets, for their excellent insulating properties. Outer layers are chosen for the expected operating range and durability. Each layer is separated by a mesh or fine netting and coated in a fine layer of vacuum deposited aluminum, to increase its reflectivity and absorptivity.

Like any blanket these not only keep heat out when the outside is too hot, they can also keep heat in when the outside is too cold. Both these techniques keep the spacecraft temperature stable and even. For many small spacecraft that's all that's necessary, preventing too much heat from getting in or out keeps the components in their operating ranges. However often some components have very narrow ranges or wildly different ones. When we worry about the heat produced inside the spacecraft being too much then we have to include internal thermal control systems.

When you think about cooling something many times the first thought is to use water or ice. A variation on that idea is ablative cooling. An ablative coating is one that rests on the component and melts or evaporates. Instead of increasing the temperature of the component all the heat goes into melting or evaporating the coating.

Coating that evaporates, of course, is gone and can only be used once. But one closely related method is to use wax. Heat melts the wax when the component is on, the wax radiates that heat away and cools. When cool the wax settles and solidifies. When the component turns back on the wax melts again, absorbing all the heat. Obviously this is only useful when the component is turned on and off in a cycle, it's no use for always on components.The easiest way to remove heat from a component that produces too much is to simply add a large mass to absorb that heat. Heat sinks are pieces of metal that conduct heat away from the source. Instead of increasing the temperature of the component the heat goes into the heat sink.

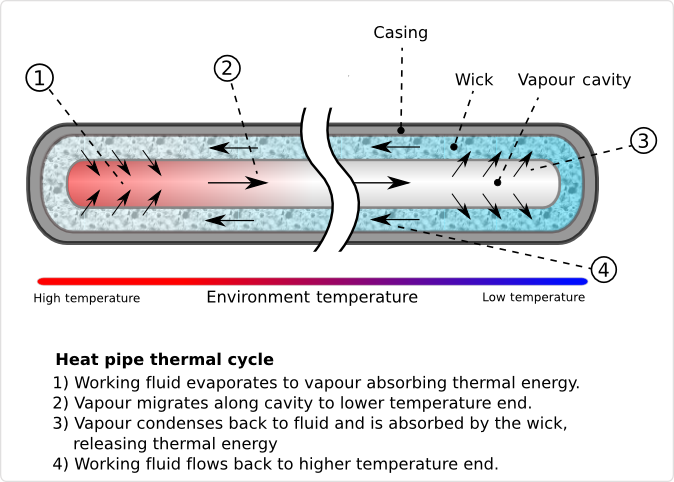

Another kind of heat sink is a heat pipe. Unlike the heat sink this time the method of moving the heat isn't a solid, but a fluid. A heat pipe is a hollow tube filled with a fluid (called the working fluid) that is near its evaporation temperature. Near the source of heat the fluid evaporates. Gas is less dense and less viscous than liquid, so it is pushed into the center of the pipe. The hot gas wants to expand, so it pushes its way through the tube to the cold end. Here is gives up its heat and condenses. The hot gas coming in pushes the liquid back towards the hot end.

Heat pipes are themselves a particular variant of a fluid loop. Heat pipes are a passive fluid loop, generally when we refer to a fluid loop, though, we mean an active loop. In this case it isn't evaporation pressure than causes the working fluid to move, but rather compressors and pumps. The fluid starts out cold, it moves past the hot component and absorbs that heat. Fluid is now hotter than it was, moving faster, with more energy. It then passes through a cold dump, where it loses that energy. At its very simplest that's all there is, just like the heat pipe.

Fluids used for spacecraft cooling vary. Some use ammonia, or even common refrigerant used in air conditioners and refrigerators. Spacecraft that have components with very low temperature requirements, like IR cameras, need something colder: liquid helium. DeWar flasks contain liquid helium, which is produced by putting helium gas under pressure until it is forced into a liquid. Condensing causes it to release its heat, cooling to very low temperature. Old spacecraft released their helium as they used it, their lifespan limited by the size of the flasks. As compressors have gotten smaller and more efficient new spacecraft can recycle helium into a fluid loop. The system compresses the helium at the end of the loop to re liquify it, and the limit to its lifetime is the life of the compressor parts.

No matter which of these systems we use we have to do something with the heat once we've removed it from the systems. We need to have some method of heat rejection. Heat rejection is how we release heat from the vehicle into space, the opposite of environmental heating.

Again often on earth when we think about getting rid of heat we think of water. Water evaporates taking the heat with it. On a spacecraft we use a similar idea, called a flash evaporator. We mentioned it before, one of the early method of using DeWar flasks. Fluid moves past the heat source, taking heat with it. Heated fluid is dumped overboard, removing heat from the spacecraft. Though effective this obviously has a limited lifespan, and is primarily used to remove excessive heat for short periods of operation, not as a long-term method of heat rejection.

Just as the only way heat can enter the spacecraft is radiation, so too the only way a spacecraft can release heat is through radiation. We use radiators to reject heat from a vehicle into space. Radiators are just panels, either on the skin of the spacecraft or out from it, with large surface area exposed to space. Most of our internal thermal control systems remove heat from a hot source to a cold source, the radiator is that cold source. They can be the opposite end of the heat sink, heat pipe, or fluid loop.

Radiators have to emit heat, but we don't want them to absorb it. We want our radiator to have a low absorptivity to emissivity ratio. A way to improve that ratio is the use of a second surface reflector. This is a two layer radiator. The top layer is a high emissivity, but is also transparent. The lower layer has a high reflectivity. Incoming radiation is reflected by the second layer and passes back out. Heat is passed from the second layer to the outer one by conduction, in essence we get the emissivity of one layer and the reflectivity of the other.

Now, radiators are good for removing heat from the spacecraft. Sometimes, though, we don't want them to. After all the heat coming in changes, sometimes we might not want to radiate heat. Louvers allow us to control the emissivity of the radiator. Louvers are rotating vanes that can be open or closed. When open they expose a radiator below them to open space, when closed they reflect that heat back into the spacecraft. Open louvers make a radiator with high emissivity, closed louvers make one with low emissivity. If the louvers are closed the spacecraft retains more heat, if they are open it emits more heat.

So we can remove heat from a component and we can reject heat into space. But we don't just have one component in a spacecraft, we have many. And each has a different operating range, and each produces a different amount of heat. Fluid loops don't just go from hot reservoir to cold reservoir, there are many heat sources. So we start with the component that has the lowest operating regime and we take the fluid there first, when it is coldest. We move fluid from place to place in order of how much heat it must remove. If we have a component that must be heated in order to work we might add a heater to it, or we might add it after the working fluid has heated up. If the fluid is warmer than the component then it will warm the component instead of cooling it. Then the working fluid goes to a radiator and compressor and moves along the loop again.

For most spacecraft that is where environmental control ends. The only important environmental factor is temperature. However sometimes we don't just have electronic components and cameras on a spacecraft, sometimes we have people on board too. Manned missions introduce a number of new challenges.

First the habitat, where the crew works and lives, must be in the proper temperature range. The human comfort zone stretches from 15 to 20 degrees centigrade, though people can tolerate much greater extremes, most people enjoy a room temperature of right around 21 degrees. The habitat also must provide all the necessary requirements for human life.

Let's consider a crew member a device which, in addition to doing work, converts input materials into output. An average human being consumes 840 grams of oxygen, 3,520g of water, and 620g food each day. Simultaneously he produces 1,000 grams of carbon dioxide, 2,280g of moisture, and 170g waste. All these outputs must be removed or otherwise dealt with while we supply all the inputs.

Air is the most obvious. For short duration flights we can often ignore food and water, waste, and other problems, but we can never ignore oxygen. A person needs at least 14 kPa of oxygen (that is the pressure of pure oxygen, or contribution of oxygen to total pressure, partial pressure) to survive. Below this, even in a pure oxygen environment, the body can't get enough and the person begins to asphyxiate. At most a person can tolerate 48kPa of oxygen, any more leads to oxygen toxicity, a potentially lethal problem known to deep sea divers.

We can't use pure oxygen, however. Oxygen doesn't just support life, it also supports fire. The more oxygen is present the easier it becomes for fire to exist. A pure oxygen environment contributed to the Apollo 1 fire, killing three astronauts during an early pad test. On Earth we live in a low oxygen environment, only 20% is oxygen. The rest is mainly nitrogen, so that's what we do in space. Nitrogen is nonflammable and largely nonreactive, so we make our spacecraft atmosphere 80% nitrogen to reduce combustibility.

Some spacesuits use a pure oxygen feed, it reduces the pressure and makes them easier to move it. However it also requires almost an hour of pre-breathing for astronauts before performing an extra-vehicular activity (EVA). Using the same concentration as the habitat relieves this requirement, but reduces the astronaut's mobility in the suit.

For missions lasting more than a few hours we also have to worry about the crew getting food and water. A human drinks 2 liters of water each day, and when we include things like washing and bathing that quickly increases to 20L. Spent water can be recycled for washing, known as grey water, but drinking water must be fresh and clean. Recall that fuel cells produce water as a by product, this is one possible source of clean water for the crew to drink. Otherwise we have to carry it.

Likewise we have to carry food. Often astronaut food is freeze-dried to save space and to extend its shelf life. With packaging the minimum amount of food can easily increase to 2kg per day per person that must be carried into orbit.

Once the astronaut has completely finished with the food there is waste that must be dealt with. At one time intimate contact devices were used. This is a polite term for diapers and even more uncomfortable bags and tubes placed over or in the appropriate body parts. Now suction toilets are used. Suction doesn't work nearly as well as gravity and can be uncomfortable for all involved. Typically the waste is jettisoned to burn up in the atmosphere once removed. Sometimes it is collected and returned to Earth for analysis by flight medics.

That isn't the only form of waste produced by the human body. People also produce moisture in the form of sweat and released by breath. People produce heat. These must be removed from the environment, as in space there's no reason for hot air to move as their is on Earth. Fans are used to circulate air and force air through filters to remove hairs, skin cells, and moisture.

People also flood the air with carbon dioxide, which must be removed so they can continue to breathe. CO2 scrubbers remove carbon dioxide from the air. On the shuttle scrubbers known as LiOH canisters were used. Lithium-hydroxide chemically reacts with carbon dioxide, removing it from the air. After a while the canister becomes saturated and can no longer remove CO2 from the air, and the canister must be replaced. The ISS uses the US made Carbon Dioxide Removal Assembly (CDRA) and the Russian made Vozdukh. Both of these systems remove carbon dioxide from the air and vent it into space.

All the systems we've talked about just now are open loop systems. In the beginning we input food, oxygen, and water; in the end we remove carbon dioxide and waste. But we need to store or carry those inputs and the outputs are useless to us. A closed source system would recycle the outputs back into new inputs. There is a device here on Earth we're all familiar with that converts carbon dioxide into oxygen at the same time as it converts waste into food and filters water. It's called a plant. These amazing devices cannot yet be carried in space effectively and used as a life support mechanism. It isn't possible yet to fully anticipate how complex an ecosystem needed so support large scale growing is, nor is there room in on the ISS, or any flight, for agriculture. Though a simple and obvious solution, bioregnerative life support is still on the drawing board.

- electronics: -10 to 45 deg

- batteries: 0 to 10 deg

- IR detectors: -269 to -173

- solid state particle detectors: -35 to 0

- motors: 0 to 50

- solar panels: -100 to 125

Temperature is a measure of how much energy is stored in a substance. The atoms making up a substance are constantly in motion, in fluid they move around each other freely, in a solid they vibrate in place. Temperature measures how much they move around, how quickly they flow past one another or vibrate.

Heat is a means of transferring that energy. When something cools it releases heat it gives up some of that energy it contained. When a substance is heated heat enters it and the motion increases.

An object can produce and release heat at the same time. If it releases more heat than it produces then it cools, and temperature goes down. If more heat comes in, or is produced, than leaves then the temperature goes up. When the two are exactly equal the temperature remains constant, and we say the object is in thermal equilibrium.

That's where we want to keep our spacecraft systems, holding steady at their operating temperatures. In addition to producing heat inside an object, heat can be transferred in three different ways.

Conduction occurs inside a substance. The motion of atoms causes them to collide with each other, spreading their energy. You can see this very clearly if you try to grab a metal bot handle. Metals are good heat conductors, they transfer their energy easily. Conduction occurs when one part of an object is hotter than another and stops when the whole object is the same temperature. Conductivity is the measure of how easily an object transfers heat, heat transfer rate depends on that and the difference in temperature along the length of an object. For a rod with a cross-section A:

Convection occurs when a fluid passes over a solid wall. At the surface conduction happens at a tiny scale between the two, and also occurs in each substance away from that surface. We call the whole effect together convection. Convection depends on the temperature of the fluid and the wall, as well as the transfer constant between them:

Convection also happens inside a fluid when heat in one part of the fluid causes it to move. Convection causes hot fluid to move up, or away from walls, because it is less dense and less viscous.

Radiation occurs in all substances, solid or fluid. Atoms in a substance have energy from their temperature. In addition to motion some of this energy excites the atom, changes the energy level of its electrons. If the energy is so great they leave the atom it's called ionizing the atom and if that happens to the whole substance it becomes a plasma. But more often the electrons are excited for a short time and then fall back to where they were. When that happens they release electromagnetic radiation, or a photon. At higher temperatures the energy of the photon emitted increases. At first its invisible infra-red light, most heat stays here. But as the heat increases it can raise to the visible spectrum. If you've ever seen a piece of iron or steel in a forge or furnace you've seen this effect. Red hot steel is hot enough that it radiates in the visible red spectrum. As it becomes hotter it starts releasing yellow light in addition to the red, so it looks orange. Even hotter and it releases higher frequencies too, which together makes it look white. Iron is literally glowing hot, it's producing light, when it is red or white hot.

Radiation output of a substance depends on its surface area and temperature, obviously. These are related to the radiative heat output by the Stefan-Boltzmann Constant (the Greek letter sigma) and a material property known as the emissivity (Greek letter epsilon). Emissivity is the ratio of how much radiation a substance could put out, to how much it actually puts out. It ranges from zero to one. An object with an emissivity of one is called a black-body, a perfect radiator often used in physics as an ideal model. At zero the body doesn't radiate at all, which also doesn't happen in real life, though some objects come close to one extreme or the other.

Bodies don't just emit heat radiation, they also absorb it. The ratio of how much heat comes in to how much heat the substance absorbs is the absorptivity:

Besides absorbing the radiation the substance can also reflect some back into space and transmit some through it. The ratio of how much transmitted through is called transmissivity, the ratio of how much is reflected is called reflectivity.

Incoming can only do these three things, be absorbed by the material, reflected back by it, or transmitted through it. So all three terms must add up to one:

A spacecraft usually isn't in contact with any other solid object, or moving through a fluid. The only means of heat transfer between the spacecraft and its environment is radiative. Environmental heat sources for a spacecraft in low earth orbit begin with the sun. Direct sunlight is the greatest source of heat, averaging around 1358 watts per square meter of skin exposed to it. Some sunlight is indirect. When sunlight comes to earth some is absorbed and some reflected (it's too thick to transmit light well) earth's albedo reflects that light. The amount of heat coming from earth's albedo varies drastically depending on position, a value used to design for is about 407 watts per square meter. Finally some of the heat from earth has nothing to do with the sun. Earth, after all, has temperature and radiates like any other body. For a spacecraft in LEO earthshine accounts for 237 watts per square meter. Unlike direct sunlight or albedo this is constant, earthshine doesn't depend on position. The side facing earth always experiences this, while direct sunlight ceases whenever the spacecraft is eclipsed by the earth. During eclipse one side is subjected to earthshine and the other has no incident heat.

So we need some method of limiting, or at least evening out, the environmental heating a spacecraft is exposed to. We call means of controlling heat into the spacecraft external thermal control.

One method is to simply prevent any one side from facing the source of heat for too long. When the spacecraft is on the day side of the earth one side is facing the sun at over 1300 watts per square meter, the other side is exposed to less than a fifth from earthshine. By simply rotating the spacecraft in roll which side is constantly changing. This method, popularly known as the barbecue roll. It takes time for the spacecraft to heat up when exposed to the sun, rotating the spacecraft prevents any one part from getting that time. As it's facing a colder direction is is radiating that heat out.

A barbecue roll can slow the skin of the spacecraft heating up. But we still worry about heat passing through the skin, to the more heat sensitive components. Temperature sensitive components are covered by insulation to prevent heat from getting to them. Multi-layer insulation (MLI) is the common method. MLI is, as the name implies, composed of many thin layers of insulation protecting the spacecraft, each with low transmissivity. Multiple layers are used because the radiation between layers is much slower than the conduction through a single thick layer. Inner layers usually use Mylar and Kapton sheets, for their excellent insulating properties. Outer layers are chosen for the expected operating range and durability. Each layer is separated by a mesh or fine netting and coated in a fine layer of vacuum deposited aluminum, to increase its reflectivity and absorptivity.

Like any blanket these not only keep heat out when the outside is too hot, they can also keep heat in when the outside is too cold. Both these techniques keep the spacecraft temperature stable and even. For many small spacecraft that's all that's necessary, preventing too much heat from getting in or out keeps the components in their operating ranges. However often some components have very narrow ranges or wildly different ones. When we worry about the heat produced inside the spacecraft being too much then we have to include internal thermal control systems.

When you think about cooling something many times the first thought is to use water or ice. A variation on that idea is ablative cooling. An ablative coating is one that rests on the component and melts or evaporates. Instead of increasing the temperature of the component all the heat goes into melting or evaporating the coating.

Coating that evaporates, of course, is gone and can only be used once. But one closely related method is to use wax. Heat melts the wax when the component is on, the wax radiates that heat away and cools. When cool the wax settles and solidifies. When the component turns back on the wax melts again, absorbing all the heat. Obviously this is only useful when the component is turned on and off in a cycle, it's no use for always on components.The easiest way to remove heat from a component that produces too much is to simply add a large mass to absorb that heat. Heat sinks are pieces of metal that conduct heat away from the source. Instead of increasing the temperature of the component the heat goes into the heat sink.